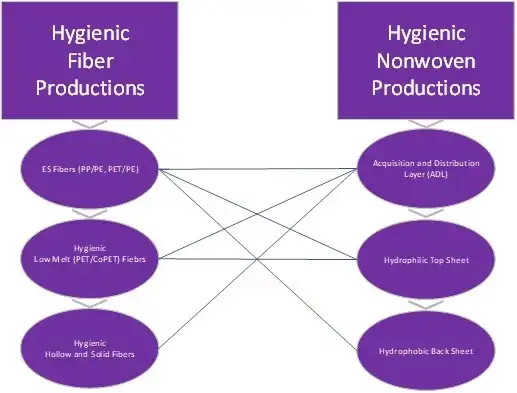

Below is a scheme of SHIVA FIBER Hygienic production and the final use of its hygienic fibers in each hygienic nonwoven material.

However please notice that this scheme is not exclusive and every Hygienic manufacturer based on its own engineering and technology can use Hygienic fibers in different mixtures and formulas.

ES Fibers

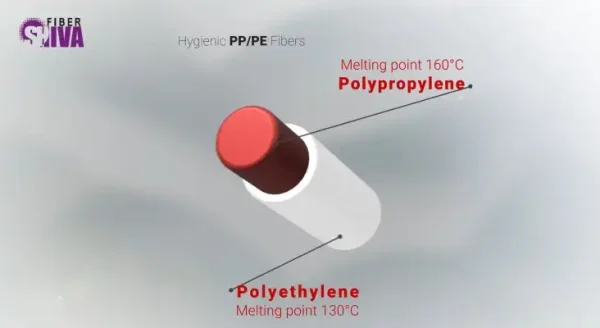

PP/PE

ES Fibers firstly invented by Japanese manufacturers are mainly Bi-component fibers having a core of Polypropylene (PP) with a melting point of about 160 degrees and a sheath of polyethylene (PE) with a melting point of about 130 degrees, as shown below.

This type of ES Fibers is mainly used for the production of Hygienic nonwovens which are in contact with human body such as hydrophilic top sheets that are in direct touch with the baby and ladies’ bodies in products like diapers and daily pads.

Since PE is a human-friendly polymer and also its softness after melting it is used to give a great touch such as natural materials when used in nonwoven technologies such as Air Through Bonding (ATB).

Es Fibers are treated with hygienic finishing and based on the customers’ demand hydrophilic/hydrophobic characteristics. In SHIVA FIBER the hydrophilic finishing is multi-wash and can be used for the premium materials.

Usually, ES Fibers with Hydrophobic finishing are used to produced ATB hydrophobic back sheets for use in the last layer of baby diapers or lady pads etc.

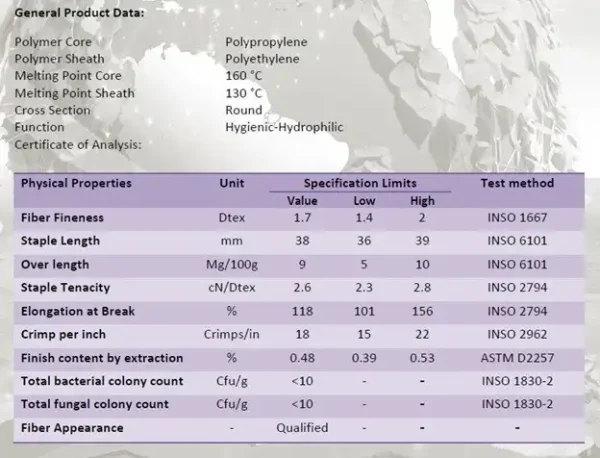

At the moment the main characteristics of ES Fibers (PP/PE) in Shiva Fiber are as below with a usual cut of 38mm. However, for orders of volume changing the characters such as denier and cut length is possible.

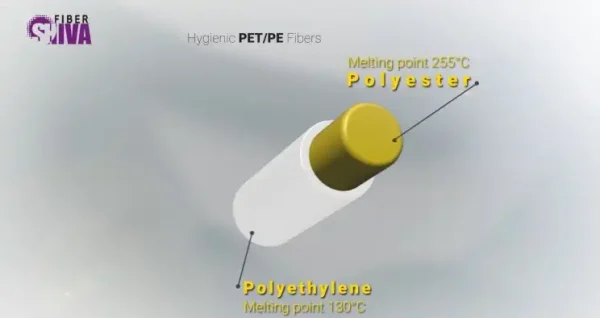

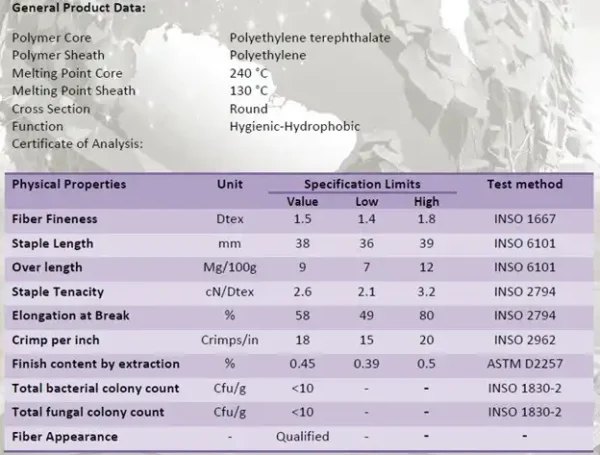

PET/PE

Another type of ES Fibers produced by SHIVA FIBER as well as other well-known global producers are Bi-Component fibers having a core of Polyethylene terephthalate (PET) with a melting point of about 240 degrees and a sheath of polyethylene (PE) with a melting point of about 130 degrees, as shown below.

Exactly like its similar PP/PE fiber since PE is a human-friendly polymer and also its softness after melting it is used to give a great touch such as natural materials when used in nonwoven technologies such as Air Through Bonding (ATB). However, because of the existence of PET in the core the final product will be kind of bulkier and fluffier.

Es Fibers PET/PE are treated with hygienic finishing and based on the customers’ demand hydrophilic/hydrophobic characteristics. In SHIVA FIBER the hydrophilic finishing is multi-wash and can be used for the premium materials.

Usually, ES Fibers with Hydrophobic finishing are used to produced ATB hydrophobic back sheets for use in the last layer of baby diapers or lady pads etc.

At the moment the main characteristics of ES Fibers (PET/PE) in Shiva Fiber are as below with a usual cut of 38mm. However, for orders of volume changing the characters such as denier and cut length is possible.

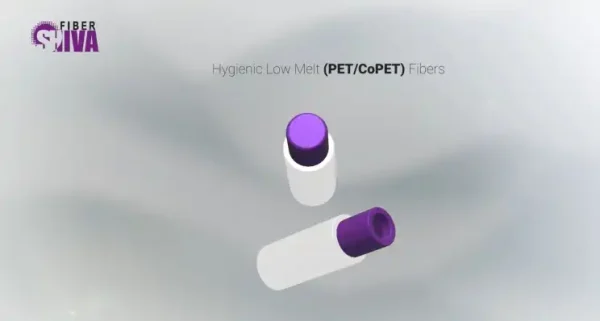

Hygienic Low Melt (PET/CoPET) Fibers

Based on experience and invention of the new technologies such as Air Through Bonding (ATB) in order to produce hygienic nonwovens such as ADL (Acquisition and Distribution layers) and so on the use of PET/CoPET fibers with the Hygienic and Hydrophilic finishing found its way to the hygiene industry. Having a core of PET with a melting point of about 240 degrees and more and a sheath of CoPET with a metling point of about 120 degrees this innovative fiber is produced by SHIVA in two Solid and Hollow types.

According to the user’s engineering this type of Hygienic Pet/CoPet fiber can be used in ADL, Top sheet or back sheet or any other nonwoven material which needs high bonding and at the same time the ability to manage liquid movement. Of course, because of PET characters, the final product produced by this fiber is not so fluffy unless mixed with other types of hygienic fibers.

At the moment this product is Solid format is being produced by 4D/51mm characters which can be changed based on the customer’s demand on the larger volumes.

Hygienic Hollow and Solid Fibers

In order to produce optimum level hygienic nonwovens and based on experience and engineering we found out that using only ES Fibers or Hygienic PET/CoPET is not leading to the premium quality. In every layer a mixture of other fibers such as Hygienic Hollow and Solid fibers can give a better touch and function to the final product. At SHIVA FIBER we produce 100% Virgin Hygienic hydrophilic Solid and Hollow fibers with different deniers and characters in different colors based on customer’s demand and volume.

Acquisition and Distribution Layer (ADL)

ADL is a layer which is used mainly in baby diapers, lady pads etc in order to absorb liquid and distribute it through the product so as to prevent rewet and leakage of the liquid and provide better dry feel.

At SHIVA Fiber we produce ADL with two carding and 4-doffer technology between 22 to 80 GSM. However, the main production is 40 and 60 GSM. The final packing for ADL can be both Reel (Spool) or Roll based on the customer’s demanded sizes and machineries.

Top Sheet

Hydrophilic top sheets produced by SHIVA FIBER Hygienic fibers and ATB technology gives a dry and soft anti-bacterial touch to the human body and improved the final product’s quality.

At Shiva Top sheets are produced with three final patterns: Normal, Embossed and Perforated. The main range is between 15 to 70 GSM. The main production is 15 and 24 GSM.

Hydrophobic back sheet

These hydrophobic layers are ideal for the end layer of baby diapers and lady pads usually sealed by a PE Film to protect the liquid leakage.

Reference : Linkdin