ES Fibers, ES (PP/PE) Fibers

ES fibers, which is shortened to Ethylene-propylene side by side, which was first produced by Japan's

JNC Group and is used in various non-woven technologies, including Through Air or Air-Through

Bonding, to produce products or delicate sanitary layers such as ADL layer in Diapers, sanitary

napkins, Top Sheet and Back Sheet are used.

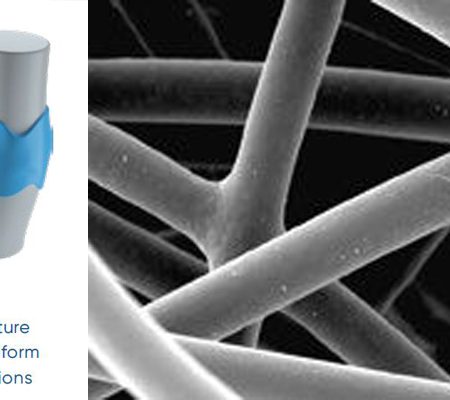

Usually, the surface of these fibers or its sheath is made of PE, which has good softness and a lower

melting temperature than the CORE, which is made of PP. Of course, there are also ES fibers with

PP/PP or PP/PET materials, in the case of polyester core, the strength of the final layer is higher.

This type of fiber is usually cut in two categories, 3 to 30 mm and 25 to 90 mm, and various properties

such as hydrophilicity, hydrophobicity, etc. are added to it depending on the customer's request.

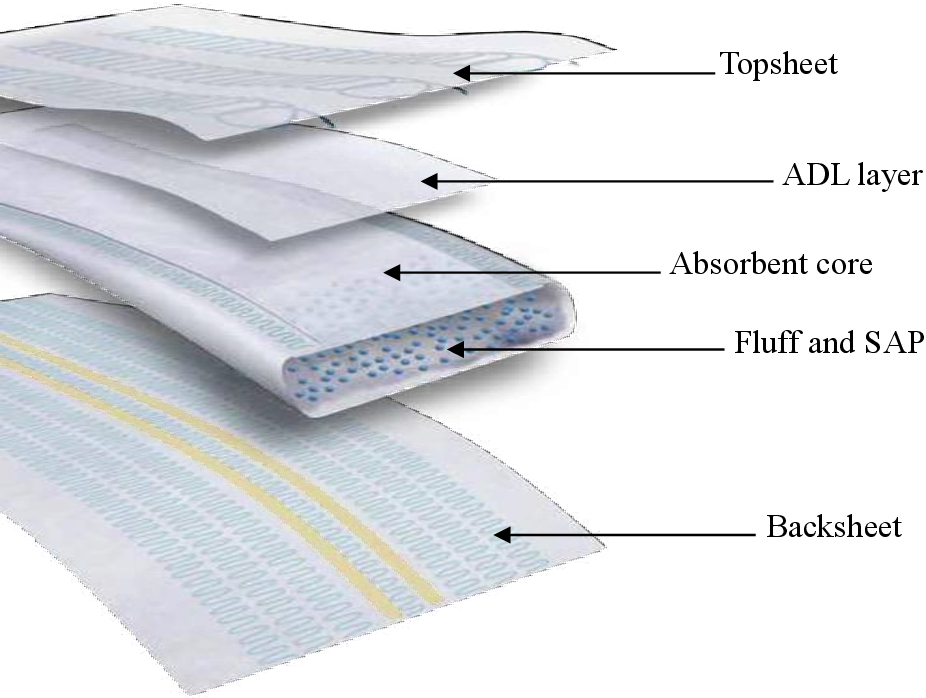

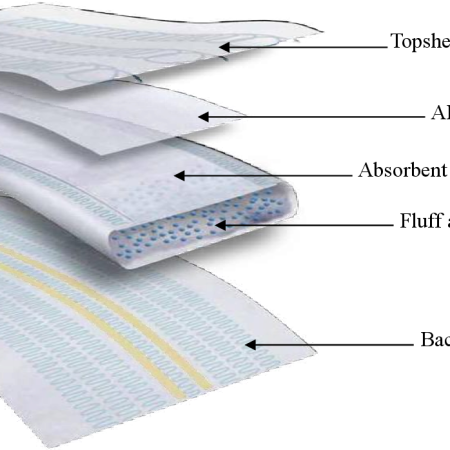

The ADL layer produced from these ES fibers is actually abbreviated as Acquisition and Distribution

Layer, which is also called absorption and diffusion layer in Farsi. This layer is used in sanitary

products such as baby diapers and women's sanitary pads as one of the layers of these products to

spread moisture and prevent skin and body sensitivity and irritation.

The ES fibers produced in the Shiva Fibers Group are one of the best options for the production of

absorption and diffusion layers and bring good quality to health products.